Process / Chemistry

Do you want to control fluid flows ?

CFD-Numerics collaborates with industrials in order to optimise their processes from efficiency, environmental and safety point of view.

- Mixing

- Powders

- Chermical reaction

- Bubbles column / water treatment

- Phase change

- Metal production

- Cement production

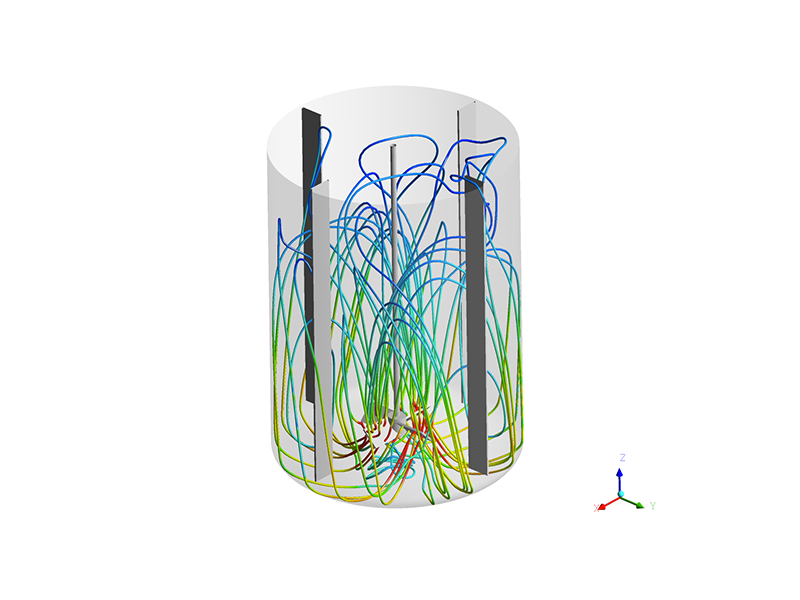

Mixing

A large number of processes use mixers.

CFD-Numerics carried out the validation of the simulation procedure for propeller mixers by comparing the power number and flow rates against tests.

The method has been extended and validated for mixtures of sludge.

Powders

The models available in the CFD software make it possible to simulate the flows of powder taking into account the interaction of the particles with each other.

CFD-Numerics has developed numerous models for fluidized bed transport, dosing of powders, mixing, suspension …

Chemical reactions

Phenomena such as catalysis are simulated to optimize the feeding of the catalysor by the gases and the thermal design of the structures..

Bubbles column / water treatment

Multiphase flows with gas bubbles are often used in chemical and water treatment processes.

CFD-Numerics has developed in-house expertise regarding the models and laws of coupling between the different phases to accurately describe the transport of bubbles.

These models are even coupled with source terms to simulate electrolysis.

Phase change

Most of the different types of phase change can now be simulated with acceptable accuracy.

CFD-Numerics uses evaporation, boiling and condensation models for gas / liquid phases.

For solid / liquid passage, we can treat solidification and casting.

Metal production

All the stages of production of metals can be simulated by CFD: from electrolysis in aluminum baths to continuous casting processes, through the heat treatment phases

Cement production

Energy issues are very important in this sector and CFD-Numerics is carrying out studies to help reduce the risk of loss of efficiency on the torch by controlling the quality of secondary air.